Understand How CPVC Pipes Better Resists Biofilm Formation

The resistance to biofilm formation is a critical factor when evaluating the suitability of materials for plumbing pipes. CPVC pipes, with their advanced composition and surface characteristics, have proven to be less prone to biofilm development, thus offering a more hygienic solution over other materials.

What is a Biofilm?

Biofilm is a slimy substance consisting of bacteria colonies that adhere to surfaces, particularly within moist environments like the insides of water pipes. These bacteria biofilm formation communities can include harmful pathogens such as Legionella and E. coli, posing significant health risks.

Why Biofilm Resistance is Important in a Piping Material

Resistance to biofilm in pipes is crucial in plumbing materials as it directly impacts water safety and quality. Accumulations of microorganisms can lead to health concerns and impaired water quality, and can even affect the taste and smell of the water. Ensuring biofilm resistance in piping materials is essential for the health and safety of all water users.

How CPVC Inherently Resists Biofilm Formation

CPVC's resistance to biofilm stems from its composition – it is made of 67% salt, an unfavourable medium for bacterial growth. The smoother interior of CPVC pipes and their superior corrosion resistance make them less hospitable to bacteria forming biofilm, preventing the attachment and growth that are conducive to biofilm formation.

CPVC’s Superior Performance in Resisting Biofilm Formation Compared to Alternatives

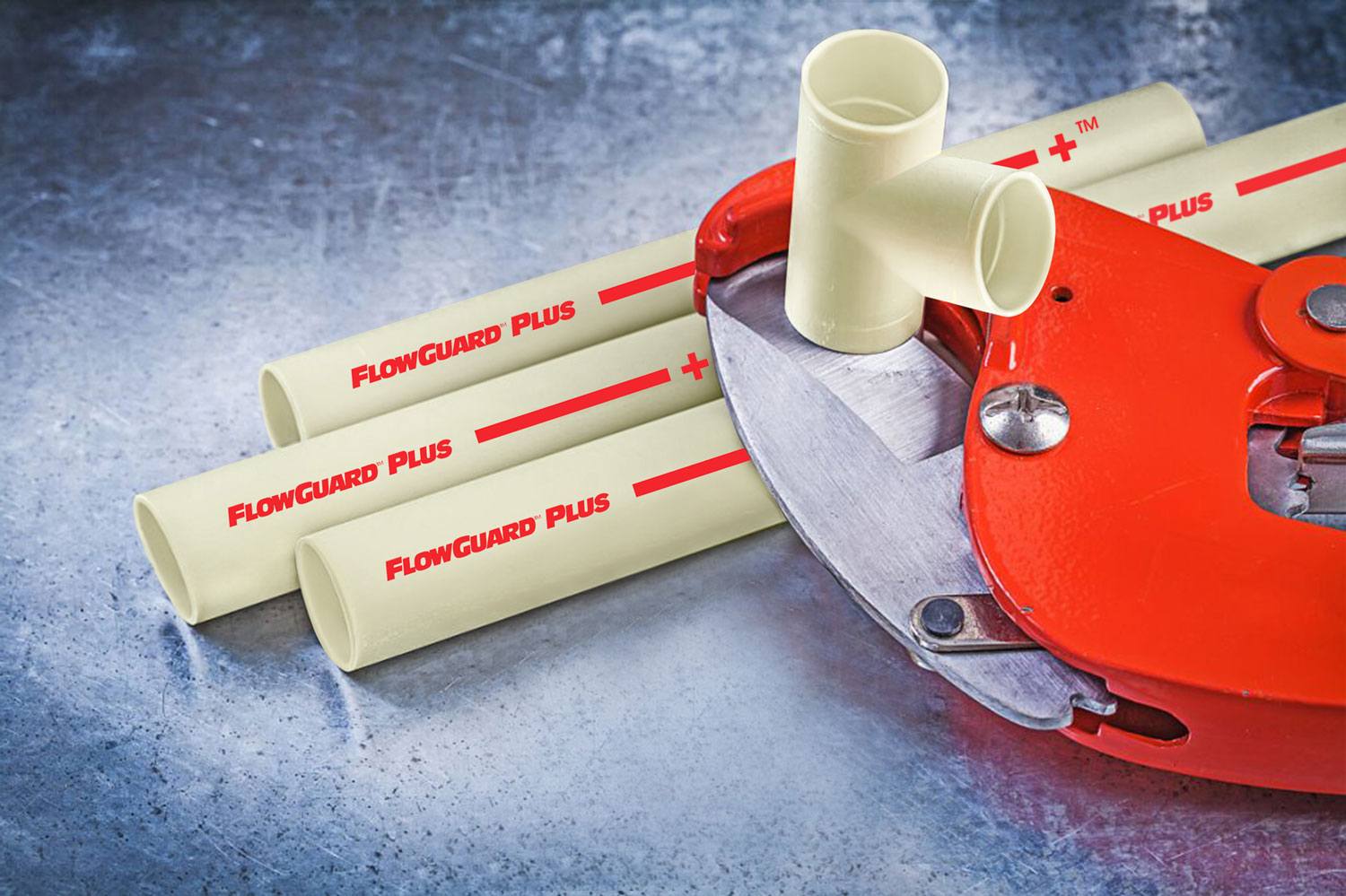

Studies have shown that CPVC pipes have lower biofilm formation potential compared to copper and polypropylene (PPR) pipes. The FlowGuard Plus CPVC pipes, for example, demonstrate significantly less biofilm formation and lower counts of Legionella bacteria, which is particularly dangerous in showerheads and faucets where water vapour can be inhaled.

CPVC Piping System Characteristics That Prevent Biofilm Formation

The characteristics of CPVC piping systems that prevent biofilm formation include:

- No Plasticizers: CPVC pipes do not contain plasticizers, which can be a source of nutrients for bacteria.

- Higher Density Material: The high-density nature of CPVC reduces the area where bacteria can attach and proliferate.

- UV Resistance: FlowGuard Plus CPVC contains UV-blocking additives, ensuring the integrity of the pipe even with exposure to sunlight, which can otherwise accelerate the growth of biofilm in water pipes made using less resistant materials.

Moreover, major international agencies have validated FlowGuard Plus CPVC for potable water applications, underscoring its suitability for maintaining water quality. For those looking to remove biofilm from water pipes, CPVC offers a robust framework for prevention and is conducive to effective cleaning methodologies, surpassing other materials in ensuring long-term water safety.

Decoding Biofilm Resistant Properties of CPVC

The selection of CPVC pipes for plumbing systems is a strategic choice for engineers and builders who prioritise long-term water safety and quality. With its inherent resistance to biofilm formation, the CPVC compound stands out as an ideal material for plumbing systems, especially in regions with hot climates or where water safety is of utmost concern. As you plan your next plumbing project, consider the biofilm-resistant properties of CPVC, and feel free to reach out to our team of piping system consultants for a deeper discussion on FlowGuard Plus CPVC's benefits.

FAQs

1. How is biofilm formed?

Biofilm formation begins when free-floating bacteria in the water adhere to pipe surfaces and start to produce a slimy, glue-like substance. This substance, composed of polysaccharides, proteins, and nucleic acids, allows the bacteria to anchor themselves more permanently to the surface, where they continue to grow and divide. Over time, more bacteria join, forming a complex, multi-layered community. Biofilms can form on any surface that has both moisture and nutrients available for the bacteria.

2. How do you remove biofilm from water pipes?

Removing biofilm from water pipes can be challenging and typically requires a multi-step approach:

- Mechanical Cleaning: This can involve flushing the pipes with high-velocity water or using tools designed to scrub the interior surfaces of the pipes.

- Chemical Disinfection: Applying disinfectants like chlorine or other specialised biofilm-removing chemicals can help break down and remove biofilms.

- Pulsed or Shock Disinfection: Periodic high doses of disinfectants can be used to shock the system and dislodge biofilms.

It is essential to follow safety guidelines and possibly consult a professional when using chemical methods to ensure effectiveness and prevent damage to the plumbing system.

3. How do you detect biofilms?

Biofilms can be detected in several ways:

- Visual Inspection: In some cases, biofilms can be seen as a slimy coating inside pipes or fixtures.

- Water Testing: Testing water for unusual levels of microbial activity can indicate the presence of biofilms.

- Professional Evaluation: Plumbers and water treatment professionals can use specialised tools and tests, such as ATP (adenosine triphosphate) testing, to detect the presence and extent of biofilm formation.

Prasenjit Misra

Prasenjit Misra, an accomplished professional, having extensive exposure in plumbing field, currently holds the position of Lead Demand Creation & Business Development of TempRite South Asia division at Lubrizol India.