Solvent Welding CPVC vs. Heat Welding PPR: Which is Better?

Installation is a significant factor in the time it takes to complete a project, the long-term reliability of the plumbing system, and the overall job cost. Each of these factors contributes to your ability to win a plumbing job, and its profitability.

For this reason, plumbers can benefit by being more proactive with their piping material recommendations to home and building owners.

Material Joining Methods

In Africa, CPVC and green pipe (PPR) are the two primary piping materials. Green pipe is joined together using heat fusion. In other words, the piping ends are heated to a melting point, pushed together, and then allowed to cool. While a reliable joint is created, the seam is not as strong as the material itself.

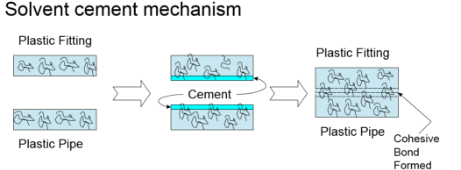

CPVC piping systems are assembled using solvent cement. Solvent cement chemically fuses the pipe and fittings together at the molecular level, creating one continuous piece of plastic. The resulting seam becomes the strongest part of the entire system.

Why the Joining Method Matters

1. Required Tools

To install CPVC with solvent cement, all a contractor needs is a can of solvent cement and a dauber less than half the width of the pipe opening. This allows for fast, consistent application of the solvent cement, even in confined, hard to reach areas.

Conversely, PPR requires a heat source be able to reach all sides of the seam. This requires an electricity source be readily available, and room to effectively heat the seam all the way around. In tight areas, the piping may actually have to be prefabricated to ensure even heat application.

2. Skill

Heat fusion requires a skilled hand. When two superheated pieces of pipe are pushed together, or a welding rod is applied, a bead of material may form around the inside of a pipe. This bead can restrict water flow, and create eddies, where microorganisms like to grow.

With solvent cement, after basic instruction anyone can join CPVC pipe and fittings. In addition, thanks to the tapered end of the pipe, the solvent cement is dispersed evenly around the joint, rather than being pushed down into the seam. This avoids bacterial growth, doesn’t reduce the internal diameter of the pipe and ensures full flow rate.

3. Long-Term Reliabillity

Thanks to the solvent cement process, the joint becomes one piece of plastic that is twice as thick as the piping itself─it cannot be pulled apart or broken. When it comes to system reliability and ultimately the reputation of the contractor, nothing is more reliable than CPVC.

As noted earlier, PPR seams are joined by melting the plastic together. The applied heat inherently weakens the original material quality, and even though the two pieces are fused together, the bond isn’t as strong or reliable as one made with solvent cement.

Have Questions?

Contractors around the world have taken advantage of FlowGuard® CPVC piping systems to simplify and speed up installation time as a way to increase profits and lower costs.

If you have questions about how solvent welding CPVC pipe can benefit your plumbing business, contact our team of piping systems consultants.