Top five challenges facing plumbers in 2024, and how to overcome them

Navigating the plumbing landscape in 2023 has been incredibly different to years gone by. Plumbing professionals are faced with evolving environmental, regulatory and technical challenges every day.

FlowGuard® Plumbing Systems come with a wealth of supporting resources to help plumbers deal with today's toughest industry challenges. Being one of society's most essential services, we take pride in creating CPVC plumbing materials that rise to the array of demanding challenges we are faced with today.

Let's take a look at some of the main challenges facing today's plumbing landscape and the crucial role of CPVC in overcoming them.

Public health and safety

There has never been greater awareness of the importance of public health and the prevention of water contamination, particularly since the COVID-19 pandemic. The plumbing industry as a result has been under increased pressure to demonstrate its ability to minimise water contamination.

Specifying the right pipe material is essential to this process. FlowGuard CPVC has an inherent resistance to corrosion and permeation, particularly when it comes to common additives in potable water supplies, such as chlorine. Not only does this help the pipe material to retain its strength and performance, but also the quality of the water itself.

Bacterial growth

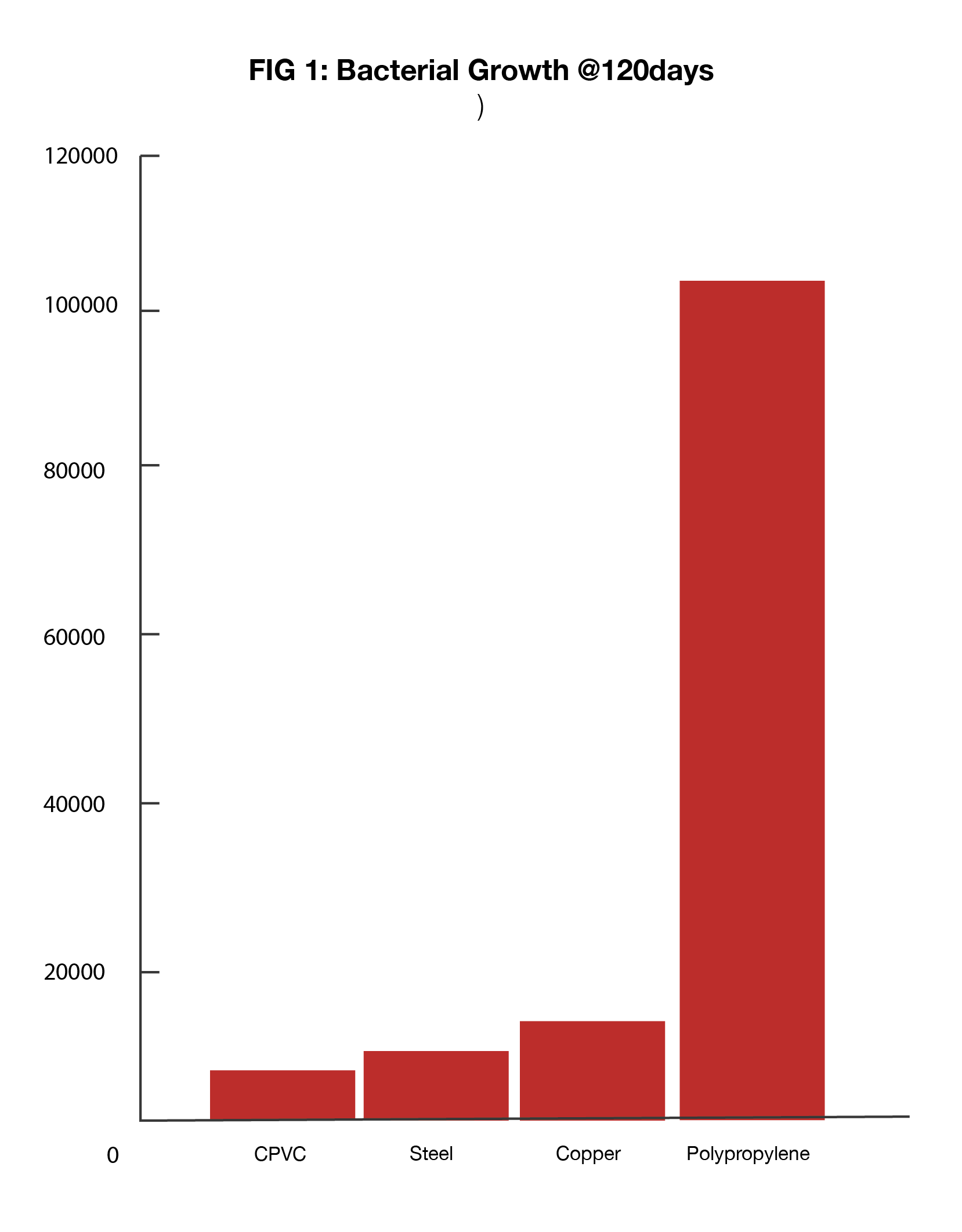

Whilst meeting the rising demands of public consumers, we must also consider the risk of waterborne pathogens in public, residential and commercial plumbing systems. The specification of pipe material used can have a significant effect on the water supply's biofilm potential and subsequent risk of contamination.

Mitigating the risk of microbial growth has never been more important. Some of the industry’s leading water safety experts have conducted research into the risk of legionella bacteria present in many common piping materials.

The KIWA water assessment analysed the biofilm formation potential in several common pipe materials, including stainless steel, CPVC, PPR and copper. Biofilm formation potential measured in CPVC was significantly lower than copper and PPR, second only to stainless steel.

Sustainability and environmental impact

A key consideration in all areas of construction and manufacturing is sustainability and the impact of building materials on the environment. The plumbing industry should be no different.

Every aspect of the manufacturing and construction process is under more stringent regulation, to ensure that the way we build our communities can be sustained for generations to come, without sustaining long-term damage.

FlowGuard CPVC is inherently stronger than many common pipe materials such as PPR, which weakens over time, even in ordinary hot and cold water supplies. CPVC is a rigid plastic pipe material that stays rigid throughout its service life.

Its impact on the environment at the manufacturing stage is also lessened, as it contains lower petroleum content than PPR, reducing the overall industry's dependence on nonrenewable resources.

Balancing cost versus quality

Here is a challenge that has always existed in the plumbing industry and, to a certain extent, it always will. Everything has an effect on your daily economic decisions; the availability of materials, your project timelines and your clients’ expectations along with those of their surrounding community.

When it comes to making smart economic decisions for the longevity of your plumbing business, specification of pipe materials must always consider durability, maintenance costs, longevity and adaptability to modern building requirements.

FlowGuard CPVC’s inherent strength and durability provides longer lasting solutions for building owners and users reducing maintenance and repair costs. The solvent cement welding technique of installation is a quick, clean and safe process that allows for fast and disruption free redesigns and remodelling when necessary.

Compliance to modern regulatory standards

This factor is perpetually affected by the previous four. The changing regulatory landscape is something all plumbing professionals must keep up with and they need to be able to trust their pipe materials in the delivery of today's standards as well as tomorrow's expectations.

Even when it comes to using CPVC material, despite all of the advantages discussed so far, it is important to specify CPVC material which actively demonstrates compliance to modern standards of water safety.

FlowGuard Plumbing Systems have been awarded the NSF/ANSI/CAN 61 AND NSF/ANSI 372 certifications by NSF International, these standards show compliance for chemical contaminants and lead contaminants respectively, in potable water.

We predict in 2024, the plumbing industry will continue to be confronted by these challenges, all of which you need to be prepared for. In a rapidly changing world of construction, the perpetual balancing act of health and safety requirements to environmental considerations to economic constraints must be handled using pipe and fitting materials you can trust.

We have technical support available to assist you in specifying the materials you need for reliable and long-lasting hot and cold water systems. We recommend exploring our plumbing resources and guidance, to learn more about how FlowGuard Plumbing Systems are protecting plumbing businesses as well as millions of homeowners, tenants and building users around the world.

.png)

-1.png)