How CPVC Piping Limits Environmental Impact

All piping materials and products have an effect on the environment. These environmental impacts range from securing raw materials needed to make different piping, to the energy required to manufacture the piping, to the ultimate disposition of the material. Because of this, homeowners must carefully consider the products that make up their plumbing system.

No matter the material—chlorinated polyvinyl chloride (CPVC) or the green pipe (PPR)—both impact the environment during production. However, the extent of this impact is dependent on the type of material.

Environmental Impact: CPVC vs. PPR

Compared to PPR, CPVC is a better material for plumbing pipes because it does less damage to the environment. A recent study conducted by an independent environmental research firm proves CPVC is less detrimental than PPR in the following categories:

- Freshwater ecotoxicity

- Human toxicity

- Photochemical oxidant formation

- Climate change

- Nonrenewable energy use

- Fossil depletion

CPVC Production Uses Less Energy Than PPR

The production and manufacturing of raw materials are equal contributors to the overall environmental impact of a material.

The production process for PPR requires more energy than the process for CPVC. Because of CPVC’s low petroleum content, its production uses fewer non-renewable oil reserves than PPR, making it a more energy-efficient process.

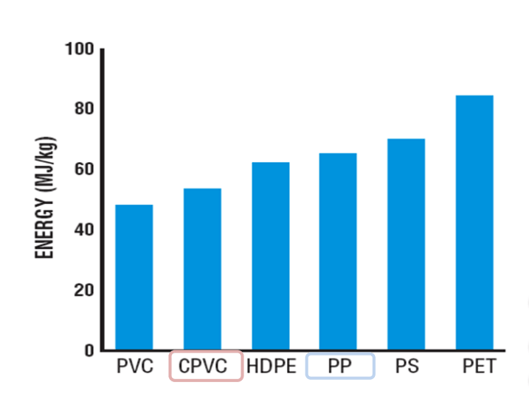

The table below shows total energy equivalent used by material during the material’s production.

CPVC is Recyclable

In many applications, PPR requires fiberglass reinforcement to meet the strength and performance requirements for its intended use. But, because of the fiberglass layer, PPR is unrecyclable.

CPVC, on the other hand, is more durable and much stronger than PPR and can be recycled into polyvinyl chloride (PVC) piping or window profiles.

CPVC piping material can also be collected on the jobsite by a specialized recycling firm and ground into pellets and granules. The pellets can be recycled and reused for different applications, including:

- Floor fillings

- Floor coatings

- Cable trays

- Speed bumps

- Car mats

Lessen Your Environmental Impact With FlowGuard® CPVC

FlowGuard® CPVC is produced using less energy and can be recycled for use in new applications. The result is less a more environmentally friendly piping material.

For more information regarding the benefits of FlowGuard CPVC and its minimal effects on the environment, contact our team of piping system consultants today.

.png)

-1.png)