How to Account for Thermal Expansion When Installing A CPVC Plumbing System

All piping materials expand and contract with temperature changes. The more significant the change, the more a pipe’s length can change. If not accounted for in a plumbing system design, the compressive stress can damage the pipe, shortening its lifespan or causing leaks.

To avoid these issues, deflection configurations need to be designed into the plumbing system. Essentially, deflection configurations take advantage of the pipe’s inherent flexibility and spread the compressive stress of an expanding or contract pipe over the length of the connecting pipe piece.

However, for these configurations to be effective, they need to be long enough so that the pipe doesn’t bend beyond its limits.

3 Deflection Configurations

Within a residential structure, there are a number of deflection points that will naturally occur in the system, while others must be designed in. Every pipe run should be paired with one of the following deflection configurations.

Use the FlowGuard® Pipe and Fittings Expansion Calculator to determine the required dimensions of your piping system deflection configurations.

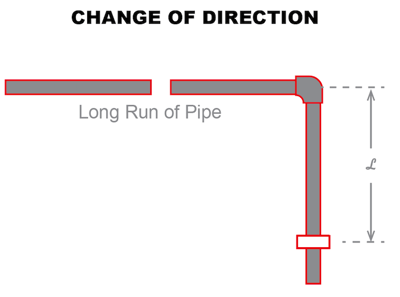

1. Changes in Direction

Piping must change direction regularly to reach all areas of a house. At these elbows, corner and adjoining pipe can allow for some degree of movement. So long as the adjoining pipe is long enough, plumbers can place a hanger or guide a defined distance away from the elbow to account for both expansion and contraction.

2. Expansion Offsets

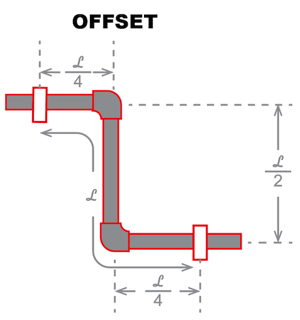

These are common occurrences in piping systems where a pipe run must avoid an obstacle, but can also easily be built into a long pipe run.

Place an offset in the center of a pipe run. Each elbow will allow for some degree of deflection as does the adjoining length of pipe. Attach the end of each pipe run to a surface using hangers or guides positioned a defined distance from the elbow.

As the pipe expands, the top and bottom elbows will push in, causing the vertical length to angle to the right. With contraction, the vertical pipe will angle to the left.

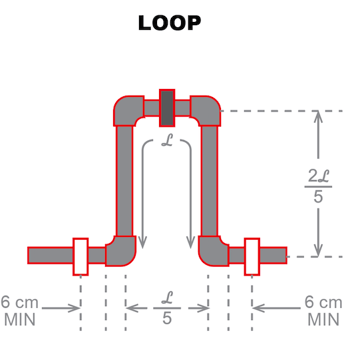

3. Expansion Loops

Expansion loops are often preferred for long pipe runs where space isn’t restricted. Expansion loops are “U”s built into the middle of a pipe run. The middle of the “U” is fastened in place by a restrain. Each side of the pipe run coming into the U is secured with a hanger or guide that allows the pipe to move back and forth. As the pipe expands, the opening of the U narrows, and with pipe contraction the U opening widens.

Expansion and Contraction Best Practices

Plumbers should follow a few best practices when allowing for expansion and contraction:

- Do not put additional stress on the pipes or fittings in an expansion loop, offset or change of direction.

- Do not restrict natural movement of the pipe in the direction of expansion and contraction.

- Always leave adequate spacing between elbows and hangers / restraints.

- Always refer to local codes and the manufacturer’s instructions.

For a comprehensive installation tutorial, view our full installation guide.

For questions or to learn more about FlowGuard CPVC Pipe , contact one of our piping systems consultants.

.png)

-1.png)