What You Need to Know About Solvent Cement Cure Times and CPVC Piping

Curing is a critical step of the installation process because the solvent cement must dry completely before you fill the pipes with water and test for leaks. If you were to pressurize and test the system before allowing the solvent cement to fully evaporate, you increase the chance of inadvertently damaging joints.

To help avoid this issue, this resource explains what’s happening as a joint cures, how long you should wait to pressure test a system, and some variables that can affect cure times.

What is Cure Time?

Solvent cement is the substance used to join chlorinated polyvinyl chloride (CPVC) pipe and fittings. When solvent cement is applied to the surface of a pipe and fitting, it softens the material surfaces of each piece. As the pipe and fitting are pressed together, the softened surfaces of the pieces intertwine and fuse together.

As the solvent cement evaporates, the material surface hardens, locking the two pieces together. This process is called “curing.”

When all the solvent cement has evaporated, the joint is considered fully cured, and can safely be pressure tested.

General Cure Times

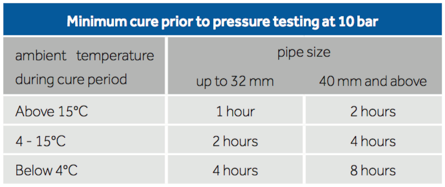

You should consult with the solvent cement manufacturer to identify the recommended cure times. That said, the table below provides general solvent cement curing recommendations.

What Affects Cure Time?

Different variables can affect how quickly the solvent cement can evaporate out of a joint. Each of the following should be considered:

- Pipe size: Smaller pipes tend to cure faster than larger pipes. In this case, size includes both pipe diameter and wall thickness.

- Temperature: Heat speeds up the evaporation process, so the hotter the day, the more quickly a joint will cure. In hot, arid climates, always make sure the pipe and fitting surfaces are wet before joining the pieces.

- Humidity: The more moisture present in the air, the less space there is for solvents to evaporate, extending the cure times.

Want to Learn More About Cure Times, Solvent Cement and CPVC?

We want to make sure you get the support and information you need for your project. If you have any questions about FlowGuard® CPVC pipe and the appropriate cure times specific to your solvent cement, our team of piping system consultants is ready to talk.