Integrating FlowGuard® CPVC into Existing Metal Piping Systems

We have already shared the fundamentals for the proper installation of FlowGuard® CPVC piping systems that can deliver system reliability for 50+ years. Mastery of these fundamentals is so simple that, once trained in proper techniques, plumbers find that most projects can be completed with only a few handheld tools. But can FlowGuard CPVC be integrated into existing systems of copper, stainless steel, carbon steel or galvanized steel with the same ease?

The answer is yes, when operating pressures and temperatures are within the acceptable range for CPVC. The same installation basics make an integration job cost-effective and straightforward. This is good news for the engineers who have two priorities when they are planning an integration – first, minimizing downtime and second, maximizing value by keeping installed costs low while setting up the system for extended life.

When implementing water distribution system projects, it is important to note that unlike some other plastics that can suffer degradation from proximity to copper ions, FlowGuard CPVC is an excellent candidate for integration into metal systems. Due to its chlorinated structure, FlowGuard CPVC has inherently good resistance to oxidizers, and its amorphous structure and high glass transition temperature make FlowGuard CPVC much less permeable to oxidizers and metal ions than polyolefins and other semi crystalline materials.

Depending on the pipe size, several different joining technologies are available for mixed-material integrations.

Integration of FlowGuard CPVC to a Metal/Mixed System with Threaded Fittings

If the piping is two inches or less, it can be placed into service right away with threaded connections/adapters. Many kinds of small pipe adapters are available on the market, such as male and female metal-to-CPVC transition fittings. As the two fittings are threaded together, the opposite tapers force thread friction, with the outside diameter of the male getting smaller towards the end of the fitting and the inside diameter of the female narrowing with depth. This method forms the seal without the use of a gasket.

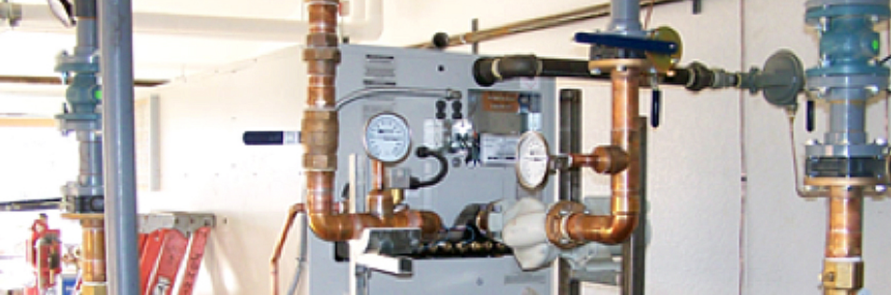

Integration of FlowGuard CPVC to Metal/Mixed System with Flange-to-Flange Connections

When the piping is 2-1/2 to 6 inches, the transition from one material to FlowGuard CPVC can occur using flanges. Even when made of different materials, flanges will stay strong and maintain the same pressure rating as the pipe and fittings, so long as they are properly bolted together.

- Measure the sections of piping to be replaced at the nearest flanges, often located at shutoff valves. More piping may be removed than absolutely necessary, but this method generally creates the strongest bond for FlowGuard CPVC.

- Prefabricate the replacement piece and its flanged joints wherever possible before bringing down the system. This leaves only a simple process to move the lightweight piping into place and bolt the flanges.

- Remove the metal flange and pipe to be replaced.

- Bolt the new flange to the one attached to the system.

Have you been approached to discuss an integration project? If you need help selecting the best approach to integrating FlowGuard CPVC with metal, as well as the FBC™ System Compatible Program’s compatible ancillary products, contact us today.

.png)

-1.png)