How Long Does CPVC Piping Last?

Reliability is arguably the most important characteristic for a residential piping system. Homeowners want piping that does its job, without problems, for as long as possible.

Chlorinated Polyvinyl Chloride (CPVC) and green pipe (PPR) are both popular piping options in today’s market. CPVC has been around for more than 55 years and many of its initial installations are still up and running without problems. PPR is a more recent addition to the market and claims to have a life-span of around 50 years―however there are no installations dating back far enough to evaluate its longevity in real-world applications.

What Makes Piping Durable?

There are two main factors that determine the service life of a piping system: corrosion and installation. Weakened material or poor installation practices will limit the long-term reliability of any piping system, material notwithstanding.

That said, CPVC offers some inherent advantages over PPR that can safeguard against corrosion and ineffective installation.

Installation and Durability of Connections

Improper installation of any piping system will lower its service life. CPVC has an edge over PPR in both the installation process and joint security:

- Installation Process: CPVC uses solvent cement to joint pipe to fittings, which can be completed on site with common, inexpensive tools by any plumber with basic training. PPR on the other hand requires specialized welding equipment and heat, which creates the risk for electrocution and a less safe working environment. PPR’s welding process also requires highly skilled laborers to ensure piping joints are properly aligned.

- Joint Security: Solvent cement fuses the pipe and fittings together, creating one continuous piece of plastic. A solvent cement welded joint becomes the strongest part of a system. PPR piping is heat welded together, limiting the strength of the overall system, and creating a bead around the inside of the pipe that slows the flow rate of liquid and increase pressure. As a result, a strain could be created on the pipe and may lead to future failure of the system.

Chlorine Resistance

Water treatment processes use chlorine and chlorine dioxide to disinfect drinking water, which is a corrosive chemical that can eat away at the interior of piping.

PPR does not resist chlorine well, which means the trace amounts of chlorine flowing through the pipes will eat away at the walls, make the pipe lose its tensile strength or lead to system failure over time. As the walls become thinner or the material loses strength, the risk of leaks and pipe damage increases. It also lowers system efficiency as the thin walls cannot maintain the same water pressure.

CPVC is a chlorinated material, enabling it to stand up very well to chlorine exposure over long periods of time. This ensures the long-term structural integrity and strength of the material.

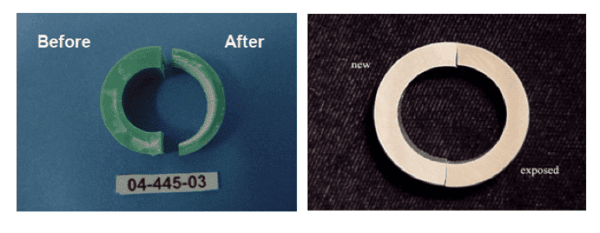

Comparison of PPR and CPVC Before and After Chlorine Exposure

Effects of chlorine on PPR (left) and CPVC (right) after nearly 10 months.

Withstanding UV Light

In outdoor settings, homeowners and plumbers should be cautious about the effects of UV rays on piping materials. UV light is a catalyst for chemical reactions, and without the proper safeguards can weaken a plastic material.

This is a problem with PPR piping because UV light instigates material oxidation (oxidation is the same process that causes metals to rust). With too much exposure, the material begins to break down to the point where the system may be more prone to leakage and bursting.

FlowGuard® CPVC integrates specialized additives into the material. These additives help protect the piping from degradation and oxidation. The only visible effect that UV has on CPVC is discoloration which does not affect pipe strength.

More About FlowGuard CPVC Piping

Looking to install FlowGuard CPVC piping for your next residential plumbing project? Contact our team of piping systems consultants today.