Can CPVC Pipe be Used for Hot Water

-

FlowGuard® CPVC is capable of handling hot water with a higher allowable operating temperature compared to PPR.

-

The best pipe for hot water line applications is Schedule 80 FlowGuard® CPVC, due to its superior temperature and pressure handling capabilities

-

Over time, FlowGuard® CPVC maintains its strength and resistance to chlorine-induced corrosion, making it a durable choice for hot water plumbing.

The process of utilising heat to shape and mold plastics into pipes and fittings is crucial for developing a home's plumbing system. Among these materials, FlowGuard CPVC and PPR stand out, but their reaction to heat, particularly from hot water and the environmental conditions, varies significantly.

This variance is mainly due to the type of plastic and its processing methods, which highlights the importance of selecting the right material for your plumbing based on how it interacts with heat.

Comparatively, can FlowGuard CPVC pipe be used for hot water systems without similar concerns? The answer lies in its unique composition. FlowGuard CPVC’s molecular structure is protected by large chlorine atoms that shield it from corrosive attacks by hypochlorous acid in chlorinated water. Should any chlorine penetrate, it would further chlorinate the FlowGuard CPVC, enhancing its durability even under elevated temperatures.

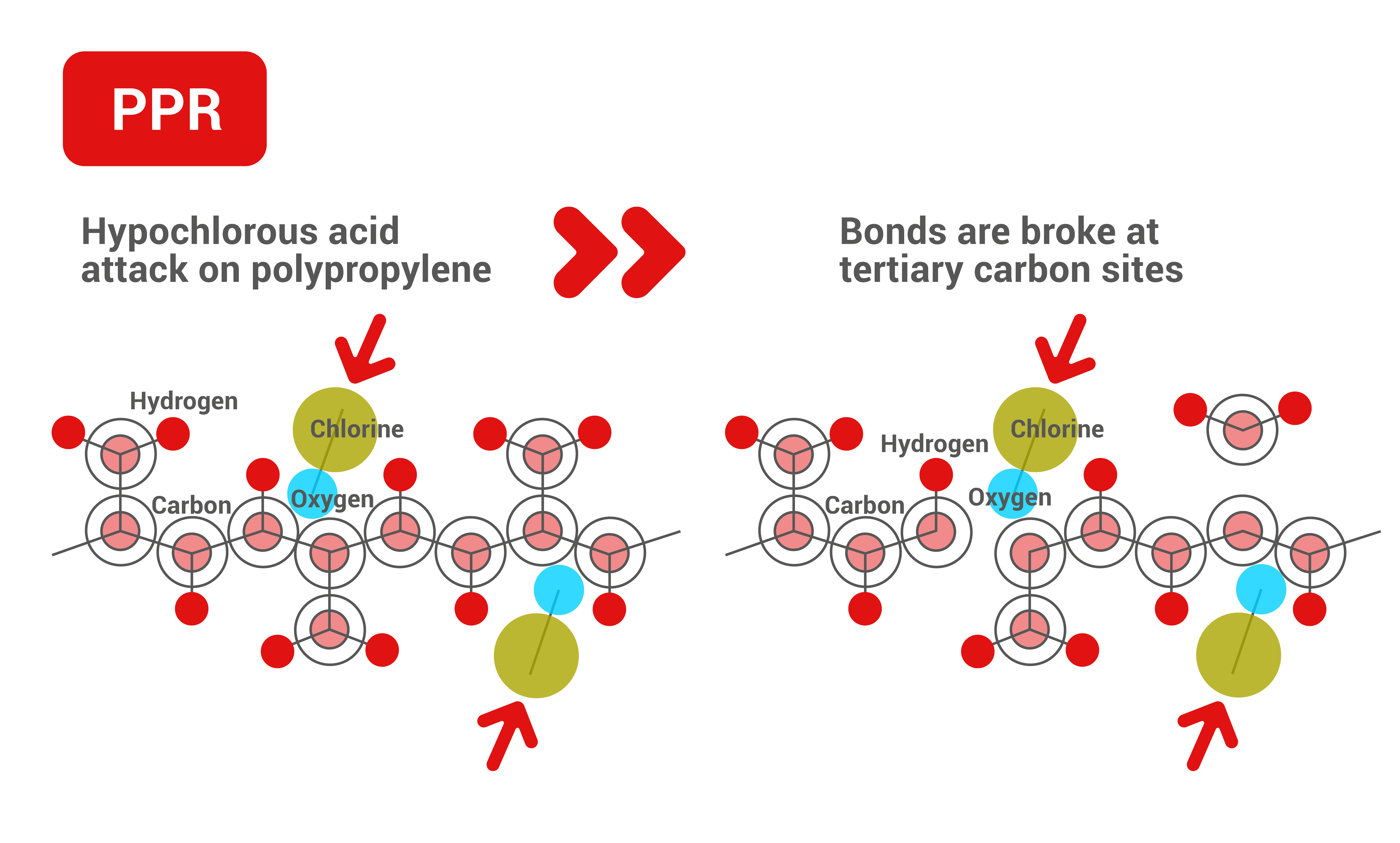

Corrosion acceleration due to heat is a known challenge in plumbing, with long-term exposure to hot water increasing the risk of material degradation. PPR pipes, despite their widespread use, are particularly vulnerable to chlorination chemicals like chlorine and chlorine dioxide used in water treatment. These chemicals break down the molecular structure of PPR over time, especially under the influence of heat which enhances chlorine's activity and penetration, leading to material erosion and ultimately, leaks.

Comparatively, can FlowGuard CPVC pipe be used for hot water systems without similar concerns? The answer lies in its unique composition. FlowGuard CPVC’s molecular structure is protected by large chlorine atoms that shield it from corrosive attacks by hypochlorous acid in chlorinated water. Should any chlorine penetrate, it would further chlorinate the FlowGuard CPVC, enhancing its durability even under elevated temperatures.

The FlowGuard CPVC plumbing pipe on the right in the image was in service in handling chlorinated drinking water for 23 years, and its wall thickness is still comparable to the new pipe shown on the left.

.jpg)

FlowGuard CPVC: The Engineered Solution for Hot Water Applications

Choosing the best pipe for hot water lines is more straightforward with FlowGuard CPVC. Engineered for excellence, FlowGuard CPVC stands toe-to-toe with hot water applications' demands. Its commendable resistance to chlorine corrosion, coupled with a heat distortion temperature exceeding typical potable water levels, renders it the ideal choice for residential plumbing, even in regions with hot climates like Saudi Arabia.

Want to learn how FlowGuard CPVC can transform your hot water plumbing system? Reach out to our team for a comprehensive consultation.

DELIVERING

RELIABILITY

For more than 50 years, FlowGuard® Pipe and Fittings has provided reliable hot and cold water plumbing systems to residential and commercial buildings around the world.

DELIVERING

RELIABILITY

For more than 50 years, FlowGuard® Pipe and Fittings has provided reliable hot and cold water plumbing systems to residential and commercial buildings around the world.

.png)

-1.png)