Solvent Welding FlowGuard® CPVC vs. Heat Welding PPR: Which is Better?

-

Plumbers can enhance project success and profitability by recommending FlowGuard® Plumbing Systems, distinguished by their quick and reliable solvent welding method.

-

Solvent welding offers a superior, seamless joint in FlowGuard® Plumbing Systems, ensuring long-term reliability and ease of installation compared to the heat fusion method used with PPR.

-

The simplicity of solvent welding allows for efficient installation in confined spaces and ensures full flow rate without compromising pipe integrity, making a FlowGuard® CPVC weld incredibly dependable.

Installation efficiency, system reliability, and cost management are critical considerations that influence a plumber's ability to secure and profit from plumbing projects. Given these factors, plumbing professionals are well-advised to actively recommend piping materials to homeowners and building proprietors.

Material Joining Methods Explored

Within the Kingdom of Saudi Arabia, the plumbing landscape is dominated by two main materials: FlowGuard® CPVC and green pipe (PPR Pipe), each with distinct joining methodologies.

Green pipe relies on heat fusion for joining, requiring the ends of the piping to be heated to melting before being combined and allowed to cool. Although this method forms a reliable joint, it does not match the original strength of the material itself.

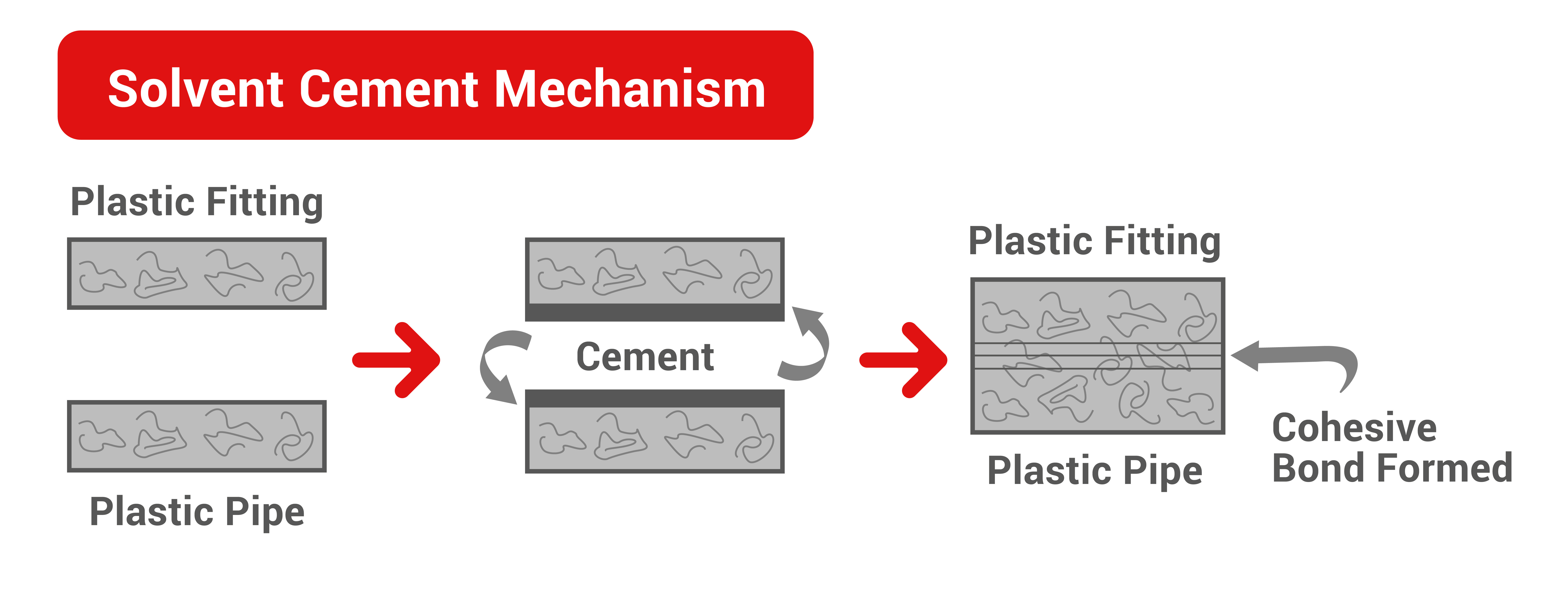

Conversely, FlowGuard CPVC pipes are united using a technique known as solvent welding. Solvent welding utilises a special cement that chemically bonds the pipe and fittings at a molecular level, rendering the joined area as the most robust part of the system.

Why The Joining Method Is Crucial

Tool Requirements

Solvent welding FlowGuard CPVC necessitates minimal tools. This facilitates quick and even application, particularly in constrained and challenging-to-access zones.

In contrast, PPR installation demands a heat source that can encompass all sides of the seam, along with an electricity supply, complicating installations in tight spots and often necessitating prefab work.

Skill Level

Heat fusion for PPR requires considerable expertise, with the risk of creating internal beads that could hinder water flow and become hotspots for microbial colonisation.

Solvent welding, on the other hand, is accessible after minimal training, promoting an even distribution of solvent cement and maintaining the internal diameter for optimal flow. This method mitigates the risk of bacterial buildup and does not alter the pipe's internal dimensions.

Longevity and Dependability

The solvent welding process transforms the joint into a singular, durable piece, doubling the thickness of the pipe at the joint and ensuring it's inseparable. FlowGuard CPVC’s reliability, cemented by solvent welding, upholds the contractor's reputation by delivering an indissoluble, sturdy pipe weld.

While PPR's seam is created by melting, which potentially degrades the material's original quality, solvent welding for FlowGuard CPVC establishes a connection that is not only stronger but more reliable over the long term.

Further Questions?

Contractors worldwide have leveraged the advantages of FlowGuard Plumbing Systems, utilising solvent welding for enhanced installation speed, reduced costs, and increased profit margins.

For insights into how solvent welding FlowGuard CPVC pipe could elevate your plumbing projects, feel free to reach out to our knowledgeable team of piping systems consultants.

DELIVERING

RELIABILITY

For more than 50 years, FlowGuard® Pipe and Fittings has provided reliable hot and cold water plumbing systems to residential and commercial buildings around the world.

DELIVERING

RELIABILITY

For more than 50 years, FlowGuard® Pipe and Fittings has provided reliable hot and cold water plumbing systems to residential and commercial buildings around the world.

.png)

-1.png)