Five Savings You Could be Making Installing CPVC

Always look for the next opportunity to save. In the trade, a few hours saved on installation or a saving on resources allocated to a build can change the direction of your success in the long term.

FlowGuard® CPVC is the answer to your next big saving, if you have ever considered any of the following:

- How long are my installations taking compared to others?

- How can I save on manpower and still get results?

- How much money is going towards expensive equipment?

- How long am I spending on repairs?

- How can I skill up without losing time on the job?

Here’s how your situation would look as an Installer of FlowGuard CPVC.

Your installation time would be drastically reduced.

While your competitors may be experienced in installing PPR, FlowGuard CPVC’s simple, quick solvent cementing process gets results faster, as this comparison video demonstrates.

|

FlowGuard CPVC pipe installation |

PPR pipe installation |

|

2:30 minutes |

6:25 minutes |

Faster installation gets you on to the next job faster, moving your business forward.

Your next piping system could be installed using a team of one.

Proper installation of FlowGuard CPVC Pipe and Fittings can be executed using reduced numbers in your team. A single installer can follow these six steps with ease:

- Cut pipe squarely using preferred plastic cutting tools

- Remove burrs and filings using a chamfering tool

- Prepare pipe for application of solvent cement with primer

- Apply solvent cement to the outside of pipe and inside of fitting with dauber

- Insert pipe into fitting socket with a ⅛ to ½ turn

- Allow for set and cure times (relative to temperature, pipe size and tightness of fit)

This process offers significant savings to you, as a full installation using a one man team frees up your Installers to progress with more projects at the same time.

You would spend no money on heat welding or electronic welding equipment.

An Installer using FlowGuard CPVC has no requirement for heat welding tools. Tools required to install PPR pipe, however, are expensive to purchase and hire, adding hours, perhaps days to your installation process along with extra transportation. The pressures of dealing with safety issues are also significantly reduced; PPR pipe requires additional force to weld heated pipes and fittings together. This process is susceptible to heat and toxin related injury.

Installing FlowGuard CPVC demands less of an upfront financial and personal investment in equipment and installation tools.

You would spend less time on repairs, and you wouldn’t need specialist tools to do it.

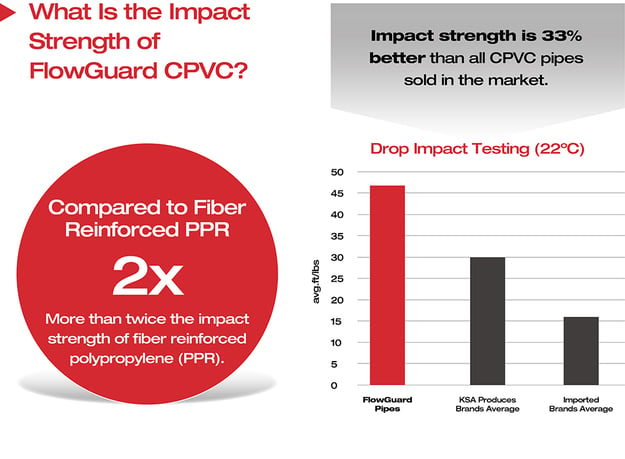

Dents, creases and cracks can appear in pipes and fittings over time, reducing its service life. For hot and cold water installations in particular, pipework requires rigorous testing to ensure optimum performance. FlowGuard CPVC has been tested for impact strength against generic CPVC and PPR:

This demonstrates a 33% increase in strength over other CPVC brands and over twice the strength of fiber reinforced PPR.

This offers long-term savings on time and equipment, delivering repairs to past projects. In fact, some of the first FlowGuard CPVC installations from 60 years ago are still in use today.

You have training resources available to you today, free of charge.

Sending Installers away to learn new practices and processes takes time away from the business. Reduce time off-site by starting your training with FlowGuard CPVC today.

The FlowGuard Pipe and Fittings Installation Guide is free to download today. Get started on the process of cutting, preparing and solvent cementing, along with proper handling and storage of CPVC.

Join our Newsletter to get advice and news delivered direct to you!

.png)

-1.png)