The Effects Of Harsh Outdoor Climates On Plumbing Pipes

Working outside in excessive temperatures presents its own set of risks and dangers, and there's never been a more apparent sign of this than the recent work restriction enforced in Saudi Arabia by the Ministry of Human Resources And Social Development. In order to protect the health and safety of workers who are exposed to direct sunlight, a work prohibition is in effect from 12 to 3pm between now and mid September.

What steps are being taken to ensure that the structural integrity of our construction materials is maintained, as we applaud efforts to safeguard the health and safety of workers? How are plumbing pipes in the Middle East and other parts of the world able to resist the extremely high outside temperatures that are observed during the summer?

Let's take a look at how FlowGuard® CPVC achieves its effectiveness and why construction projects in Saudi Arabia and beyond are not suffering from lack of productivity due to the elements.

FlowGuard CPVC is a specially formulated material that helps to withstand the effects of harsh outdoor temperatures, in particular prolonged exposure to sunlight in hot climates.

The impact of UV on plastic pipes

Ultraviolet light poses real danger to the structural integrity of plumbing systems.

UV radiation boosts the photooxidation process that occurs in plastics. When oxygen or ozone is present, photo-oxidation causes the surface of a polymer to degrade. This process is known as surface degradation. Radiant energy is essential to this process.

The molecular weight of the polymer will decrease as a result of the photooxidation process, which is a chemical change. As a result, the material undergoes a decline in its tensile strength and impact strength, making it weaker overall.

UV light is a particularly powerful catalyst for the oxidation process within HDPE, PPR and PEX materials.

The impact of UV exposure on CPVC

FlowGuard CPVC is created with specialised UV blocking ingredients such as carbon black and titanium dioxide, to withstand regular exposure to UV before and after installation. Because of the protection provided, the pressure rating of the pipe as well as its other physical features are not compromised.

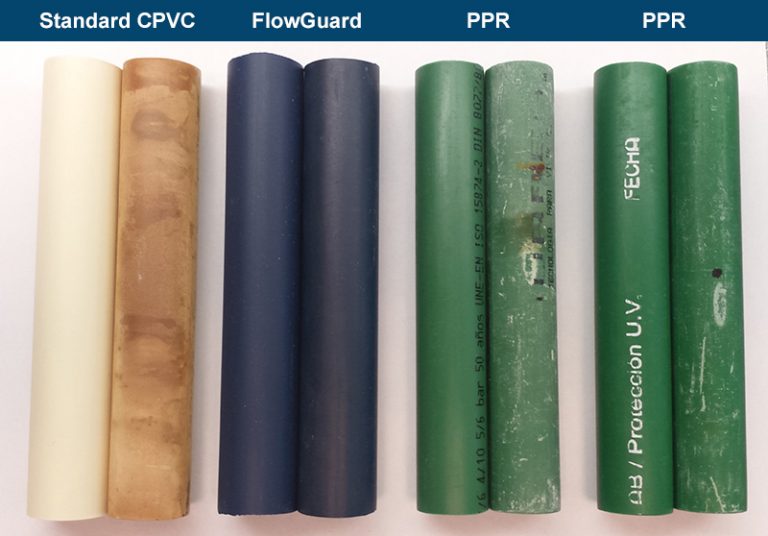

When compared to PPR, piping materials made of FlowGuard CPVC are more resistant to the destructive effects of UV rays and the free radicals that are generated as a result.

Discoloration can be a common occurrence; nevertheless, this kind of damage is entirely cosmetic and does not affect the pipe's structural integrity. There is no change in the pressure that the pipes are able to withstand, not even after prolonged exposure to UV light.

It is recommended that pipes be painted with a water based latex paint, in order to reduce the effect that UV light has on discoloration of the pipes.

Storing and handling CPVC pipe outdoors

Even though FlowGuard CPVC can withstand UV light without being damaged, we advise covering it with non-transparent material when storing outside for an extended period of time. Pipes will be better protected from the discolouring effects of UV rays using this measure.

When working with CPVC pipes outside, it is also important to keep the following in mind:

- Find a flat location, free of sharp, jagged rocks or debris that is somewhat protected.

- Keep pipes and fittings clear of areas where they may be run over by power equipment.

- Never place anything on piping that is heavy, sharp, or rough.

Installation in hot conditions

The following measures will ensure a safe and effective installation of FlowGuard CPVC outside, particularly in hot temperatures.

To guarantee that a strong solvent cemented bond is formed, wipe away any debris or moisture that may be present on the pipe and fittings. A dry environment leading to an accumulation of dust can prohibit you from building a strong cohesive bond.

When installing, it is best to make joints in areas that are cooler or in the shade; the rate at which solvent cement evaporates can be accelerated by heat. Staying in a cool environment will help ensure that the solvent cement does not start to dry up before you are ready to join pipes and fittings together.

Make sure you use the appropriate curing time. Curing times for FlowGuard CPVC can vary greatly depending on factors such as temperature, humidity, and pipe diameter. Because of the potential for higher temperatures to have a considerable impact on appropriate curing durations, it is important to always refer to the manufacturer's guidance for solvent cement curing times.

Work safely - safe plumbing is reliable plumbing

FlowGuard CPVC piping systems are designed for 50 years of service life with a safety factor of 2.

In our FlowGuard Pipe and Fittings Installation Guide, our team of product and engineering specialists provide detailed advice on how to correctly install a FlowGuard CPVC piping system to ensure that it will continue to function reliably over time.

.png)

-1.png)