Resource-Efficient CPVC Limits Environmental Footprint

For decades, the environmental movement and the green building emphasis that grew out of it, focused heavily on the contribution of manufacturing processes that emitted waste byproducts to the air, water and land. However, today one of the primary aspects of assessing sustainability in building materials is acknowledging their resource efficiency and how they perform during the use phase of their lifecycle. Products that are durable, energy efficient and have a long service life by definition have a reduced environmental footprint when compared to products that are made from non-renewable materials, or that corrode and are susceptible to early failures, requiring land disposal.

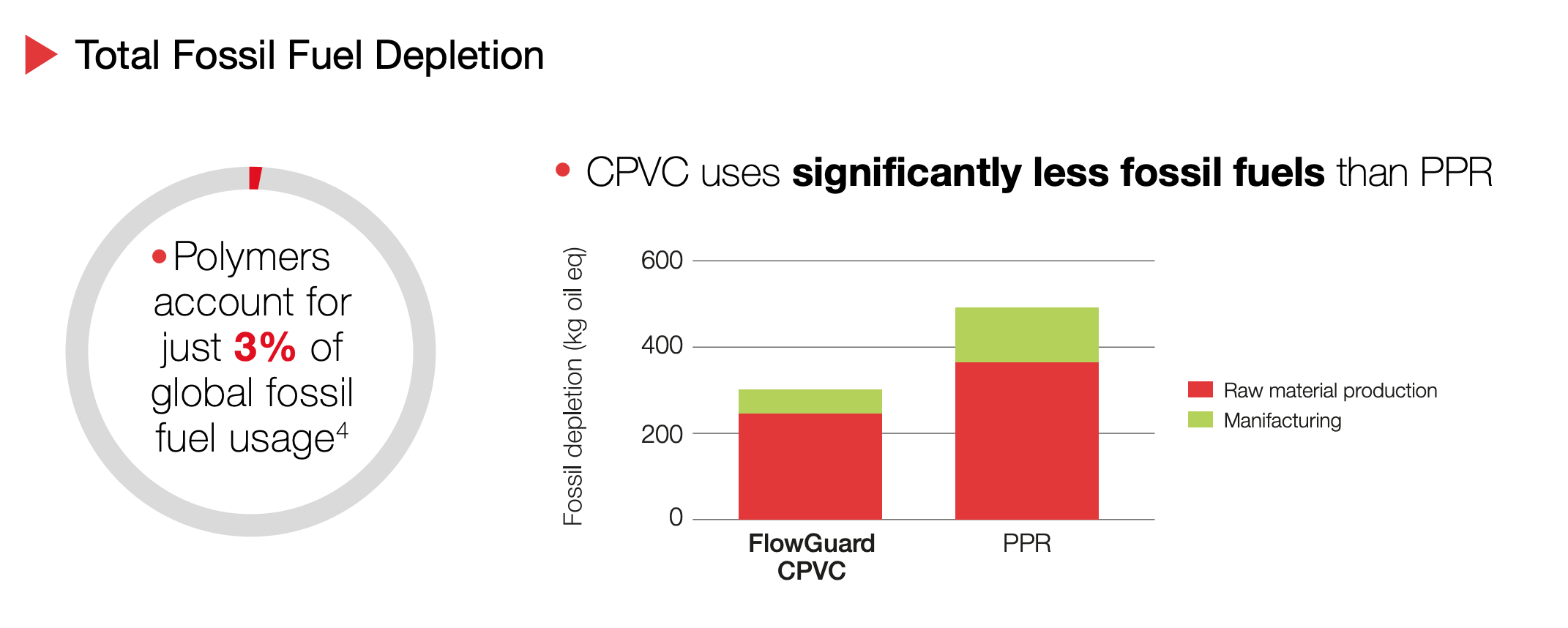

CPVC is inherently resource efficient. The compound that is used to formulate the CPVC pipe used for hot and cold water pipe and fittings derives from the same elements found in salt, a plentiful natural resource. Unlike other plastics, only a third is petroleum-based.

In addition:

- Processing and transporting CPVC piping consumes less energy than copper.

- CPVC uses far less fossil fuel in production than PP-R.

FlowGuard® CPVC Designed for Functional Top Performance

Once in service, CPVC continues to offer energy efficiency benefits. With a thermal conductivity 1/300th that of steel, a product like FlowGuard® CPVC is naturally insulating. CPVC will remain condensation-free under most environmental conditions that would cause copper tube to sweat and drip, even without insulation.

Another efficiency feature of CPVC piping is its smooth, corrosion-free inside pipe walls that safeguard the integrity of the water flow for which the system is designed. Because there is no need to compensate for corrosion and scale buildup in the overall design, FlowGuard CPVC pipe systems need only incorporate a Hazen-Williams C factor of 150, which remains constant as the system ages. The benefit is a reduced likelihood that pressure drops from friction head losses that could lead to wasteful leaks and worse.

To find out more about CPVC and a discussion of even more environmental impacts, view the infographic How Energy Efficient Is CPVC Compared To Other Piping Materials?

.png)

-1.png)