FLOWGUARD® CPVC

CONTINUES TO LEAD IN

THE MARKET OVER PEX

Leverage the reliability and durability of CPVC over traditional PEX materials

FLOWGUARD® CPVC

CONTINUES TO LEAD IN THE MARKET OVER PEX

Leverage the reliability and durability of CPVC over traditional PEX materials

We understand the pressures contractors and building owners face in understanding the performance of materials available. This approach is vital in maintaining reputations and ensuring the piping system installed delivers clean and safe drinking water for the user.

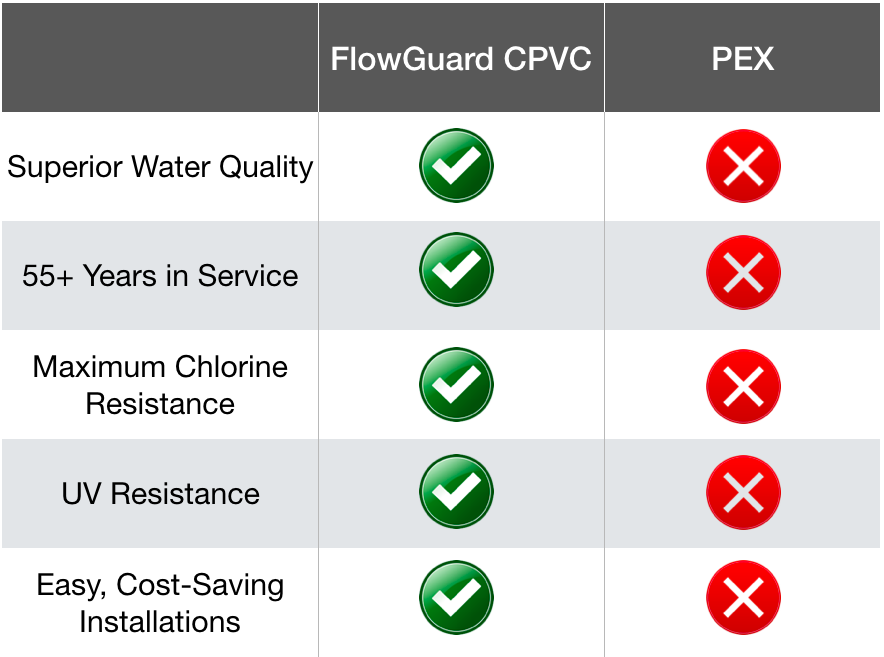

When determining which material you want to include in your plumbing system, FlowGuard® CPVC surpasses PEX in distinct areas:

Service History

The service history of a material brand is an urgent consideration in determining a material for your project.

FlowGuard® Pipe and Fittings are showcasing 60 years of consistently delivering clean, safe drinking water to millions of homeowners, tenants and building occupants.

Since the turn of the millennium, PEX systems have come under scrutiny- 10 out of 22 plumbing failure class-action lawsuits filed in the past 17 years have involved PEX systems failure due to contact with the drinking water. Statistics like these have forced PEX systems to reinvent themselves multiple times, due to concerns over product liability.

Considering the facts, it is no surprise FlowGuard® Pipe and Fittings remains the most installed plumbing system, the preferred brand of choice for new developments and retrofits.

Discover more about us and our partner manufacturers.

Water Quality

Our society relies on plumbing systems within our homes, workplaces and leisure facilities, to deliver safe, clean drinking water. Whilst some piping material can improve water quality, some are better than others at maintaining it.

In assessing water quality we have covered Biofilm potential, leaching potential and permeability.

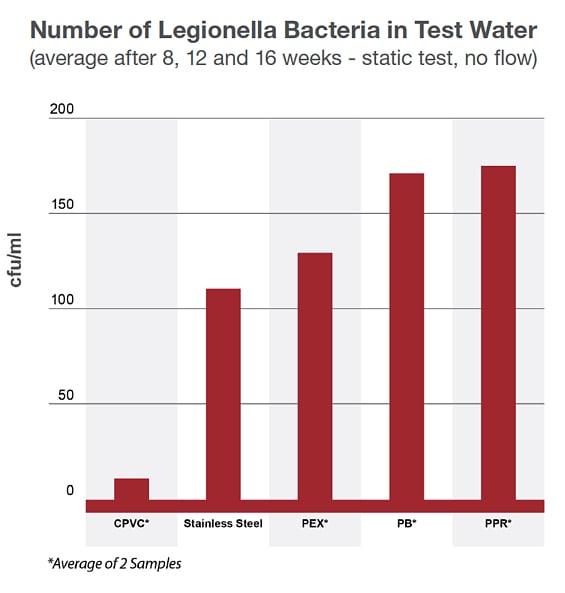

Biofilm potential

Biofilm is a collection of organic and inorganic, living and dead materials that accumulate on a surface. Biofilm can harbor harmful bacteria such as legionella that could cause health issues if consumed. There are 4 stages to biofilm formation:

- Initial reversible attachment

- Irreversible attachment- formation of monolayer and microcolony

- Maturation

- Dispersion

Third party studies show that FlowGuard® Pipe and Fittings consistently outperform PEX in biofilm formation potential, due to the internal qualities of our material presenting difficult conditions for biofilm to form.

Leaching

FlowGuard® Pipe and Fittings will not leach any substances at unsafe levels into your water supply. Our CPVC solutions are certified to ANSI/NSF Standard 61 for drinking water transport under all water conditions, irrespective of water hardness.

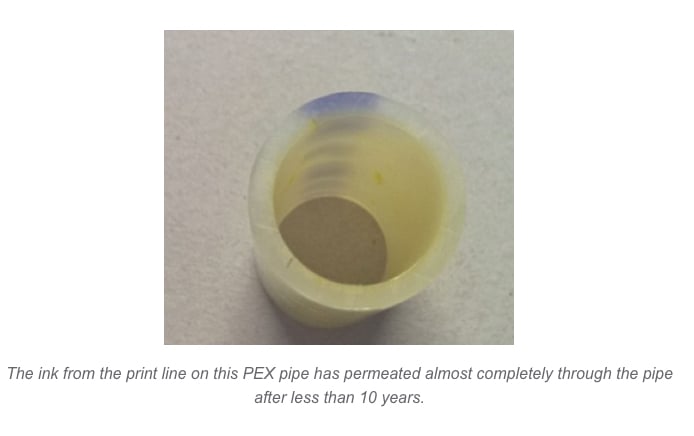

Permeability

PEX has been identified as a permeable material, meaning any contaminants that contact the outside of the pipe may be transmitted through the pipe wall, this could lead to water contamination, presenting potential health risks if consumed.

Unfortunately, there are no standard tests or published disclosure of materials that carry permeation risk with PEX, leaving homeowners, builders and plumbers exposed to future hazards and quality issues.

With any material you consider, we recommend you ask the manufacturer for a list of materials your solution should not come into contact with.

Our CPVC technology will not allow contaminants to enter your drinking water through the pipe without initiating the pipe to fail, offering superiority in permeation resistance compared to PEX and other solutions available on the market.

FlowGuard® CPVC is backed by the FBC™ System Compatible Program, enabling us to assist manufacturers in determining their product’s chemical compatibility with our material.

Find out more about FlowGuard® CPVC and Water Safety.

UV Resistance

Ultraviolet (UV) rays is a form of electromagnetic radiation that can come from the sun, fluorescent bulbs or other types of light bulbs. The impact of UV varies considerably between FlowGuard® CPVC and PEX.

PEX contains additives to protect against chlorine and chlorine dioxide degradation, UV light consumes these additives which could lead to system failure. In some cases, just four weeks of exposure to UV rays can reduce the time-to-failure of PEX by up to 21%.

While UV exposure may cause discoloration in FlowGuard® CPVC over time, under normal use conditions the pressure-bearing capability and life-expectancy is essentially unaffected.

Chlorine Resistance

Disinfectants are required to keep drinking water at a safe pH level, reducing the rates of waterborne illnesses. The most common drinking water disinfectant is chlorine, it’s therefore highly important that pipe and fittings be resistant to chlorine and chlorine dioxide.

PEX has only been tested to resist chlorine at levels up to 4.3 ppm, with the use of chlorine-based disinfectants reducing the temperature rating of PEX by 22°C (from 82°C to 60°C). In 2017, the Plastic Pipe Institute® (PPI) issued a technical note stating any combination of elevated temperatures, pressures or UV rays can significantly reduce the service life of a PEX pipe.

Hot chlorinated water is known to degrade PEX pipe, causing leaks and system failures. PEX piping, although carrying a temperature and pressure rating of 6.89 at 82°C, the pipe is not listed to perform under those conditions in the presence of chlorinated water.

FlowGuard® CPVC is extremely resistant to degradation by chlorine and chlorine dioxide due to the presence of chlorine in the polymer structure. The natural immunity of our systems ensures a CPVC system can withstand chlorinated water at temperatures and pressures, where PEX would fail.

Cost-Saving Installation

Research conducted by the Home Innovation Research Labs, a subsidiary of the National Association of Home Builders (NAHB), found CPVC installations to be about 15% faster than PEX in common configuration.

Not only is the installation of FlowGuard® Pipes and Fittings faster, but our solutions often save plumbers and builders money due to the non-reliance on expensive and heavy power tools and machinery during the installation, unlike PEX where expensive crimping or expansion tools are required.

Our systems can be installed quickly and easily, using inexpensive cutting tools and a solvent welding process that fuses the joints at a molecular level, providing outstanding strength to the system.

PEX fittings, including the body and crimp rings, typically cost several times more than comparable CPVC fittings, and can take double, if not triple the time to install. Not only are these fittings more expensive, even when properly assembled the structural integrity of the joints is questionable and has been the subject of several high-profile failures. In terms of strength, PEX does not carry the necessary rigidity necessary for use in vertical risers.

Discover why our installation processes are favoured by builders and plumbers around the world.

FlowGuard® Pipe and Fittings continues to lead in the international market, providing CPVC solutions for plumbing systems that are built to last, and offer consistently reliable potable water.

Debunking CPVC Myths

FlowGuard® pipe and fittings are a proven reliable choice for residential plumbing applications.

.png)

-1.png)