OVERCOME PPR LIMITATIONS

WITH FLOWGUARD® CPVC

Backed by more than sixty years of proven performance across varying applications, FlowGuard® CPVC has distinct advantages over PPR.

OVERCOME PPR LIMITATIONS

WITH FLOWGUARD® CPVC

Backed by more than sixty years of proven performance across varying applications, FlowGuard® CPVC has distinct advantages over PPR.

The durability and reliability of polypropylene (PPR) or 'Green Pipe', has been questioned since its inception with PPR system failures reported in diverse climates and regions. Contributing factors are usually poor installation, as well as adverse reactions to the routine disinfectants, such as chlorine, used in potable water damaging pipe integrity.

When considering the materials for your plumbing system, FlowGuard® CPVC overcomes traditional delivery challenges, outperforming PPR in distinct areas:

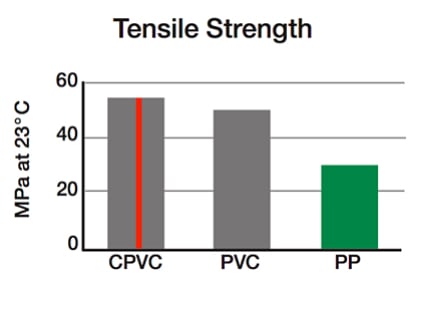

Material Strength and Rigidity

CPVC is a highly durable and robust material, enabling traders and plumbers to overcome installation, repair or modification challenges. In comparing FlowGuard® CPVC to PPR, our material has:

- 60% greater tensile strength.

- Nearly double the flexural strength.

- A higher pressure bearing capability- using a smaller pipe size FlowGuard® CPVC still has the same flow rate as PPR.

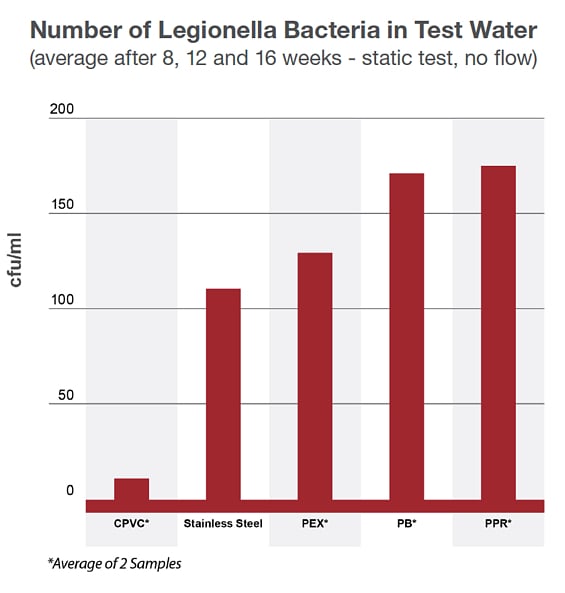

Superior Water Quality

The most valued characteristic of plumbing material is the ability to ensure consistent quality and delivery of water. The formation of biofilm impairs water quality. FlowGuard® CPVC's resistance to biofilm formation ensures water remains pure, reducing the risk of:

- Compromised water quality, including colour, taste and smell.

- Bacterial growth, including Legionella, Pseudomonas and Coliform bacterias.

- Accumulating microorganisms- many of which often cause health problems.

Multiple international studies confirm CPVC consistently outranks PPR in biofilm resistance.

Did you know FlowGuard® CPVC has been certified safe for potable water applications by leading international standards organisations? These agencies include:

- NSF International

- Kiwa

- WRAS

- ASTM

- SASO

- BSi

In fact, FlowGuard® CPVC holds an NSF 61 Annex G certification, which verifies the weighted average lead content within our piping material is less than 0.25%.

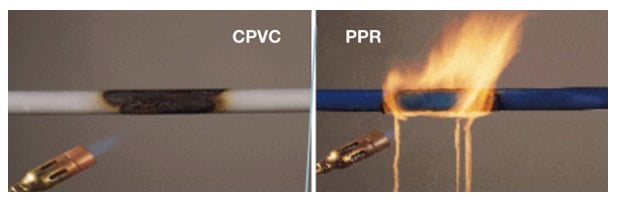

Higher Material Safety

Limiting oxygen index (LOI) is used to indicate the relative flammability of materials. The method calculates the minimum concentration of oxygen needed in the atmosphere to support the flaming combustion of a material- the higher the value, the greater the resistance to burning.

FlowGuard® CPVC has an LOI of 60, meaning it does not support combustion. PPR has an LOI of 18, defining it as a combustible material that may increase fire damage due to flaming drips falling.

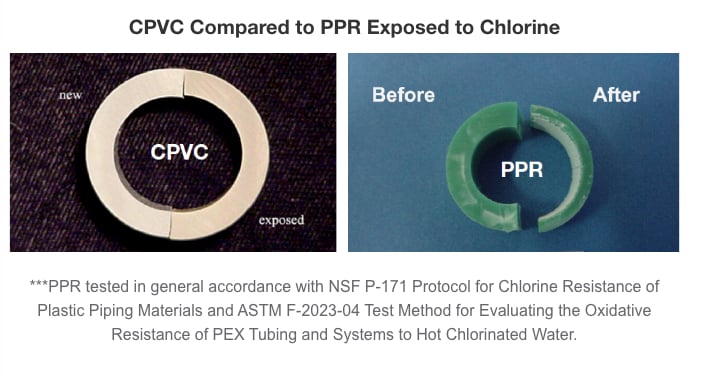

Resistant to Chlorine Impacts

Common household disinfectants, like chlorine and chlorine dioxide, can cause damage to plumbing systems depending on the piping material used.

FlowGuard® CPVC is unaffected by chlorine and chlorine dioxide found in potable water. PPR erodes in hot chlorinated water systems, making it susceptible to oxidative stress cracking, causing the pipe to flake and clog plumbing systems. The plumbing system will eventually lose the ability to hold pressure, resulting in leaks and potential system failure.

Superior Installation Process

The process of installing PPR can be complicated and may present a risk to installation teams. For the joining method, PPR requires precise power machinery to provide heat fusion at 260℃; if the ambient temperature is lower than 5℃, the heating time will increase by 50%. This method also increases the likelihood of future bead formation inside the pipe, which reduces flow rate and increases the buildup of minerals and bacteria.

FlowGuard® pipes and fittings offer a cost-effective, safe and straightforward installation, enabling you to stay on-time and on-budget. We recommend solvent cement welding as the joining method for FlowGuard® CPVC.

Plumbers and builders across the world trust in our technology and our installation process as it's:

- Quick and easy assembly regardless of space- requiring no power tools or machinery.

- The tools needed are easy to use and inexpensive to purchase.

- The cemented joints provide greater integral strength to the system.

- Installation requires no heat, devoiding the risk of fire or burns.

Debunking CPVC Myths

FlowGuard® pipe and fittings are a proven reliable choice for residential plumbing applications.

.png)

-1.png)