Should I Choose CPVC or PPR Piping?

FlowGuard® CPVC has been used around the world for more than 55 years.

CPVC’s primary competitor in certain parts of Africa is polypropylene (PPR) or green pipe. Relatively new to the market, PPR has left some homeowners, plumbers and traders questioning which is better for their home.

Our material scientists have collected research and findings from studies around the world to compare the materials side-by-side across 7 core categories.

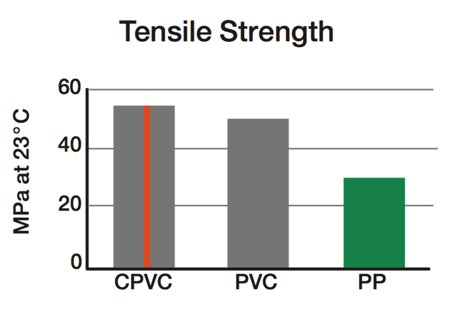

1. Physical Properties

With 60% greater tensile strength and nearly twice the flexural strength, CPVC is a stronger, more durable piping material than PPR. Due to its strength, CPVC can withstand more pressure, which means same flow rate with smaller pipes.

2. Ease and Efficiency of Installation

CPVC pipes and fittings are joined with a simple solvent cement welding process. Conversely, PPR systems are connected using heat fusion welding.

With solvent cement, CPVC piping can be installed:

- Using simple and cheap tools.

- Quickly and easily saving time and money.

- Securely — Solvent cement welded joints chemically fuse the pieces together and become the strongest part of the system.

- Without electricity.

In addition, CPVC’s rigidity requires fewer hangers and supports to be used during installation and makes it the best material for vertical plumbing and risers.

In contrast, PPR system installation can be costly and take longer since it requires special equipment and more skilled labor. Heat welding can also lead to bead formation around the inside of the pipe, thus reducing water flow rate and increasing chances for bacterial growth. Finally, it requires extra room to assemble, meaning parts of the system need to be prefabricated.

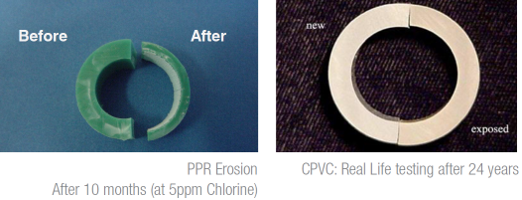

3. Chlorine Resistance

Chlorine and chlorine dioxide are often used as drinking water disinfectants. When chlorine and water mix, they can form hypochlorous acid, which is known to break down piping material.

CPVC is subjected to a chlorination process, which makes it unaffected by the hypochlorous acid that is present in the potable water supply. This results in longer service life for plumbing systems.

When exposed to hypochlorous acid, PPR does not have the same defense mechanisms, leaving it susceptible to attack. This results in oxidation stress cracking inside the pipes and erosion of the pipe wall, leaving a thinner, weaker piping material.

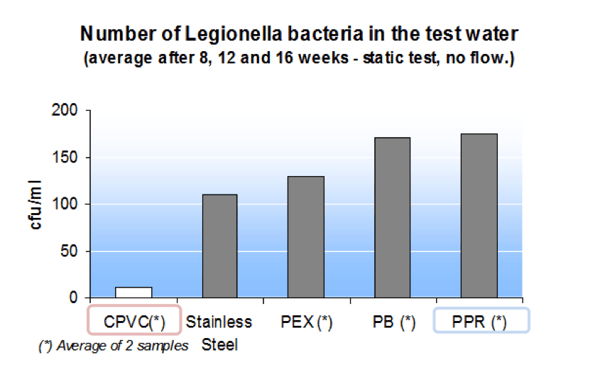

4. Bacteria Growth

Despite water disinfection, bacteria can still be present in your drinking water, and potentially grow on the inside of pipe walls. With CPVC, the smoothness of the pipe surface and lack of plasticizers discourages microbial growth.

Multiple international studies, like the one conducted by research firm Kiwa, have confirmed the superior antimicrobial performance of CPVC compared to other piping materials, especially PPR.

In the chart below, KiWA found the number of Legionella bacteria in test water to be significantly lower than that of PPR.

5. Water Safety

FlowGuard® CPVC is approved for potable water applications by all major international agencies and holds an NSF 61 Annex G certification.

NSF/ANSI 61 focuses on drinking water system components and the corresponding health effects, with a specific focus on lead. It was established to control the potential adverse human health effects from products that contact drinking water.

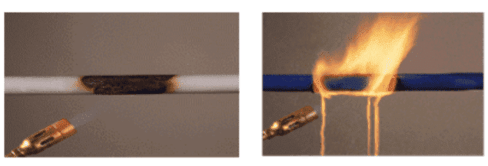

6. Fire Resistance

CPVC piping doesn’t support combustion. It requires 60% oxygen in the atmosphere to sustain a flame. Earth’s atmosphere is 21% oxygen.

To burn, the temperature would need to reach 480°C, and even then the material chars. This charring layer actually serves as a insulator, partially shielding the inner portion of piping material from the heat. CPVC has the lowest possible combustion rating for any non-metal.

PPR has a limiting oxygen index of 18, making 3x more combustible than CPVC. In addition, the material will generate more heat and increase the risk of fire damage.

7. Eco-Friendly and Sustainability

CPVC is lower in petroleum content than other plastic materials, including PPR. This means that it takes less energy to manufacture. And the end of its service life, it can be reground into pellets and recycled into new piping, or transformed into things we’re surrounded by every day─floor fillings, floor coatings, speed bumps, car mats, and more.

CPVC is the Superior Choice

Made with superior materials, FlowGuard CPVC Pipe and Fittings are backed by more than 50 years of proven performance and provide safety, durability and reliability for residential plumbing systems in the Africa and around the world.

Have questions about CPVC piping and how it can help with your next project? Contact the piping systems consultants at FlowGuard today.

.png)

-1.png)